SKC

-

CCorporation

A leading company that strive for the world’s best.

A leading company that strive for the world’s best.

-

CCreation

Global ESG material solutions company

Global ESG material solutions company

-

CCommunication

SKC is making efforts to create a better future for all of our partners.

SKC is making efforts to create a better future for all of our partners.

-

CCareer

SKC is making efforts to create a better future for all of our partners.

SKC is making efforts to create a better future for all of our partners.

● Plans to grow the market jointly with SK Chemicals and Jinyoung Global ... Strengthens mobility materials lines, including those for electric vehicles

The SK Group of Companies are exploring the automotive part materials markets under a “separately and together” strategy. With the new material film helping improve the fuel efficiency of vehicles while creating a high-value-added blue ocean, it is believed to have generated societal value, said Tae-won Chey, chairman and chief executive officer of the SK Group.

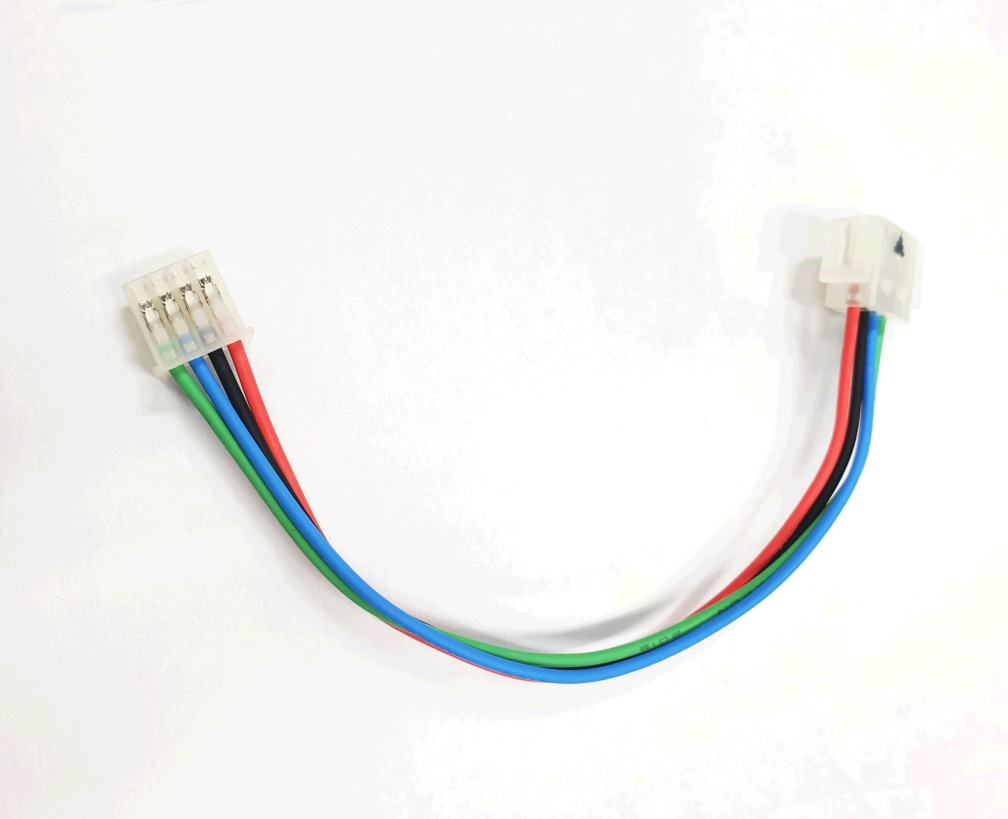

SKC (CEO Wan-jae Lee) and SK Chemicals (CEO Cheol Kim) have started the commercialized production of the higher value-added film made of super-engineering plastic PCT for the first time in the world. Used as core material for compact cables, PCT (poly-cyclohexylene dimethylene-terephthalate) film has been supplied to KIA NIRO EV.

SKC PCT film is made of PCT materials developed by SK Chemicals. PCT is widely used for automotive or electronic connectors and highly heat-resisting fiber since it boasts of high resistance to high temperature, humidity, and alkali and offers outstanding insulation performance. Although it is highly durable, it could not be extruded into the film since it has a property of hardening fast.

SKC has succeeded in extruding PCT resin into film for the first time in the world by improving the physical properties of the PCT resin through the sharing of its resources with SK Chemicals based on its film know-how accumulated for over 42 years. It has produced a “flexible flat cable” of the ultra-thin, lightweight compact film in collaboration with automotive cable producer Jinyoung Global. The two companies plan to expand gradually the market for the compact film cable, which is so far supplied to only one electric vehicle, KIA NIRO EV.

SKC paid attention to automotive film cable as PCT is a core material of compact cable that cannot be replaced by any alternatives. To be used as automotive cable, it should be highly resistant to heat and humidity. Cables made of existing materials could not satisfy these two requirements. PCT film is durable at up to 265℃ and highly resistant to humidity.

The outlook for the film cable market is very bright. Although compact cars are being developed rapidly, heavy copper cables are widely used. There is tremendous room for replacing cables. The usage of cables will grow as electric vehicles become popular, and convenience devices and other electronic automotive parts will also increase. The PCT film market will be valued at 250 billion won when all automotive cables are replaced by film-type cables.

SKC plans to increase the market together with its partners that have cooperated in the commercial production of PCT film. It also intends to conduct marketing among overseas customers jointly with SK Chemicals. In addition, SKC seeks to diversify automotive parts using PCT film jointly with Jinyoung Global. The film-type cable has been assessed to be a highly desirable material to replace the electric vehicle battery cable.

"The PCT film developed jointly with SK Chemicals is a core material that has enabled the development of compact cable, which contributes to improved automotive fuel efficiency. SKC plans to promote its electric vehicle/mobility materials lines, including specialty polyurethane suspension, specialty film for fixing the windshield, and materials for wireless battery charging," an SKC executive said. [End]

[“Flexible flat cable” -- automotive PCT film-type cable developed by SKC jointly with SK Chemicals for the first time in the world]

[Existing automotive cables]